What CAT6A keystones / RJ-45s / crimping tools should I get?

Hi,

I am doing 20 runs of CAT6A through my house, and wanted to ask if you can recommend the appropriate end point accessories / tools to do the job. Do I need special wall plates too?

Thanks.

I am doing 20 runs of CAT6A through my house, and wanted to ask if you can recommend the appropriate end point accessories / tools to do the job. Do I need special wall plates too?

Thanks.

There's nothing really special to it. I use a standard crimping tool for the RJ45 ends, a standard punchdown tool for the CAT5e or CAT6 wall plates.

I have a small network cabinet in my loft where I am terminating my CAT6 runs onto a dedicated patch panel and then using small patch leads to connect to a 19" Gigabit switch

ASKER CERTIFIED SOLUTION

membership

This solution is only available to members.

To access this solution, you must be a member of Experts Exchange.

ASKER

I have to say that I saw those same keystones as well as a reviewer saying that they don't match the 6A standard. Rather, reviewers recommended I purchase these keystones, which are more expensive:

http://www.amazon.com/Cable-Matters-6-Pack-Shielded-Keystone/dp/B00CLVAJCK/ref=sr_1_1?s=electronics&ie=UTF8&qid=1387057875&sr=1-1&keywords=cat+6a+keystones

Anyways, I shelled out $500 for 2,000' of CAT6A, so I don't want to use the wrong equipment or accessories to finish the job.

http://www.amazon.com/Cable-Matters-6-Pack-Shielded-Keystone/dp/B00CLVAJCK/ref=sr_1_1?s=electronics&ie=UTF8&qid=1387057875&sr=1-1&keywords=cat+6a+keystones

Anyways, I shelled out $500 for 2,000' of CAT6A, so I don't want to use the wrong equipment or accessories to finish the job.

Well, shielding is not part of the Cat6a spec. If your Cat6a cable isn't shielded, shielded jacks do not really add anything, since there would be nowhere to drain any induced currents they pick up, effectively making the metal jacket into an antenna instead of a shield.

For fire safety, cable that runs between floors should be riser - CMR - or plenum - CMP - rated. The cheapest Cat6a shielded riser cable I see is almost $1/foot. http://www.amazon.com/dp/B007IBQMHE

Plenum is more-expensive (e.g. http://www.amazon.com/dp/B00E5L4IEE ).

For fire safety, cable that runs between floors should be riser - CMR - or plenum - CMP - rated. The cheapest Cat6a shielded riser cable I see is almost $1/foot. http://www.amazon.com/dp/B007IBQMHE

Plenum is more-expensive (e.g. http://www.amazon.com/dp/B00E5L4IEE ).

ASKER

Are there non-shielded Cat6A keystones available?

You mean besides http://www.amazon.com/dp/B006IKHABI ?

Yes, if you want to pay more.

Did you read also the comment to the review on which you seem to have placed so much unwarranted reliance?

Yes, if you want to pay more.

Did you read also the comment to the review on which you seem to have placed so much unwarranted reliance?

ASKER

Darr247,

Thanks for pointing that out. In that case, I will go pick up a bag of those at the store and try them out. I'll get back to this question when I'm through testing them.

Thanks for pointing that out. In that case, I will go pick up a bag of those at the store and try them out. I'll get back to this question when I'm through testing them.

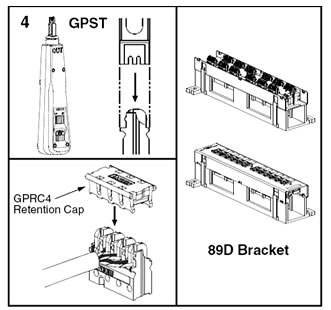

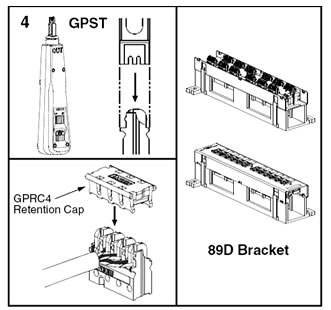

I use the Platinum Tools EZRJPRO crimper for plugs, but I recommend using factory patch cords wherever possible (and I don't find any Cat6a plugs from Platinum... only Cat6 and Cat6+, which are used with these strain reliefs)

For jacks I use the Ideal Punchmaster II. If you think you'll ever need the 66 blade for telephone terminal punchdowns, I recommend buying it from Home Depot - http://www.homedepot.com/p/203761571 (that variant with both the 110 and 66 blades is ~3x the Home Depot price on Amazon).

For jacks I use the Ideal Punchmaster II. If you think you'll ever need the 66 blade for telephone terminal punchdowns, I recommend buying it from Home Depot - http://www.homedepot.com/p/203761571 (that variant with both the 110 and 66 blades is ~3x the Home Depot price on Amazon).

ASKER

By the way, what standard should I use for the keystones and RJ-45? 568A or B?

I use 568B (which is orange's white first on the plugs), but they're really identical when you examine what they do... from one end, green is send and from the other end orange is send, no matter which standard you use. Just choose one and use it all the time and you should be good.

ASKER

well, on one side I'll be crimping on RJ 45's, and the other side of the same cable will be the keystones, so I'd rather avoid any inconvenience. does that change the standard?

No, it doesn't change/affect it... you'll still want to use the same standard on both ends.

The nice thing about keystones is they usually have the pairs right next to each other on the punchdown rows, so you can maintain the color's twist rate right up until they go into the slots. The Platinum tool and components make that possible with plugs, too... otherwise, it's not easy keeping the twist to within 1/2'' (12mm) of the ends as the spec says when using dead front plugs.

There is no standard I can find spec'd anywhere for which colors go on which side on keystones. Some jacks have the orange and green on the same side, so the blue and brown locations are the same for both A and B on the other side... but I've also seen jacks with green and orange on different sides. e.g.

The nice thing about keystones is they usually have the pairs right next to each other on the punchdown rows, so you can maintain the color's twist rate right up until they go into the slots. The Platinum tool and components make that possible with plugs, too... otherwise, it's not easy keeping the twist to within 1/2'' (12mm) of the ends as the spec says when using dead front plugs.

There is no standard I can find spec'd anywhere for which colors go on which side on keystones. Some jacks have the orange and green on the same side, so the blue and brown locations are the same for both A and B on the other side... but I've also seen jacks with green and orange on different sides. e.g.

ASKER

Crimping 22 runs of solid-core cabling will drive me insane, so I've decided to get a patch panel like roybridge recommended and use a much-easier punch-down tool instead. I'll let you guys know what happens.

ASKER

Update:

I just hooked up four keystones and it was a lot of work. The cable itself is covered with a very hard jacket which is rather inflexible and creates tension when mounting the keystones into the plastic panel and screwing it into the wall. Should I be concerned over this tension or is the copper secure in the keystone's teeth?

I just hooked up four keystones and it was a lot of work. The cable itself is covered with a very hard jacket which is rather inflexible and creates tension when mounting the keystones into the plastic panel and screwing it into the wall. Should I be concerned over this tension or is the copper secure in the keystone's teeth?

The cable should be 'dressed out' so it curves and falls naturally into place next to its neighbor, then secured with ty-wraps... while the setup might not be the same as your location, I would recommend a video like http://www.youtube.com/watch?v=Wo-wd7LC870 for a quick tutorial... though starting the strip about 100mm (4 inches) beyond the final length is recommended, then using the zip string inside it to open the jacket back to final length, and trimming off all but about 100mm (4 inches) of the twisted pairs... the guy in the video is just careful to only score the jacket (not cut through it), then bend it back and forth a couple times to 'break' it on the score line, instead of using the zip string.

Keystones typically come with a cap that snaps on after termination to secure the wires and usually even the cable... but few patch panels come with similar caps, especially the less-expensive panels. Panduit and Leviton patch panels that cost over $150 each come with retention caps like the ones in this diagram

Keystones typically come with a cap that snaps on after termination to secure the wires and usually even the cable... but few patch panels come with similar caps, especially the less-expensive panels. Panduit and Leviton patch panels that cost over $150 each come with retention caps like the ones in this diagram

ASKER

That's a little bit higher end than what I think I need. Would the following work?

http://www.amazon.com/Monoprice-110036-19-Inch-24-Port-Horizontal/dp/B00DIGBIMM/ref=sr_1_17?ie=UTF8&qid=1387691869&sr=8-17&keywords=24+port+6a

http://www.amazon.com/Monoprice-110036-19-Inch-24-Port-Horizontal/dp/B00DIGBIMM/ref=sr_1_17?ie=UTF8&qid=1387691869&sr=8-17&keywords=24+port+6a

I don't know how you're mounting it... if it's on a small wall-mounted rack, something like this plastic channel might work http://www.amazon.com/dp/B00006MJFL

Note they show it mounted vertically, but it should mount just fine horizontally above or below the patch panel, too. Or something like this belkin unit http://www.amazon.com/dp/B000067RJ2

that would allow tie-wrapping the cables to those loops near the termination point to relieve strain on the cables.

Actually, either of those should also lag-screw to a piece of plywood or between ~19'' centers 2x4/2x6 frame, too, if that's how you're mounting the patch panel.

These bridle rings are handy for routing/securing low voltage wiring, too.

http://www.zorotools.com/g/00103634

Choose the 2'' #14 lag screw for wood, or the 3/4'' 10-24 machine screw thread for small beam clamps. They also come in 2'' x 1/4-20 thread... just search 'bridle rings' there on zorotools.

Note they show it mounted vertically, but it should mount just fine horizontally above or below the patch panel, too. Or something like this belkin unit http://www.amazon.com/dp/B000067RJ2

that would allow tie-wrapping the cables to those loops near the termination point to relieve strain on the cables.

Actually, either of those should also lag-screw to a piece of plywood or between ~19'' centers 2x4/2x6 frame, too, if that's how you're mounting the patch panel.

These bridle rings are handy for routing/securing low voltage wiring, too.

http://www.zorotools.com/g/00103634

Choose the 2'' #14 lag screw for wood, or the 3/4'' 10-24 machine screw thread for small beam clamps. They also come in 2'' x 1/4-20 thread... just search 'bridle rings' there on zorotools.

ASKER

I'm going to try to improvise something using 2x4's where the patch panel will be screwed into the beams in the attic. I would prefer not to but in the interest of saving space I think that's the best option.

ASKER

Thank you, I ended up purchasing these: http://www.frys.com/product/6301341