How do I make this battery pack?

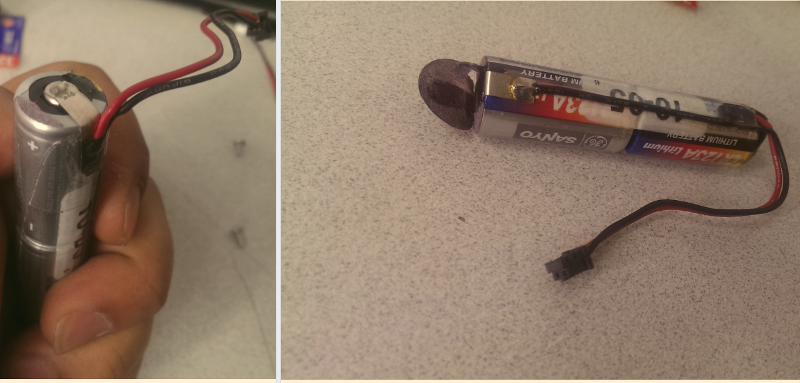

I need to make exactly like this, two 3V camera batteries connected and need the cable, then the battery pack is wrapped in tube. I can not use any battery case because this battery pack will go inside of another case. So it has to be wrapped in the plastic tube as you see in the photo.

The metal piece between the battery ends and cable doesn't look like it's soldered, but attached with some sort of stapled. Then the battery body is wrapped in some sort of tube which seems as it shrinks when heat is applied.

I can buy easily the 3V battries from ebay, but need to make the battery pack by my own.

http://www.ebay.com/itm/LOT20-CR123A-Photo-Lithium-3V-B...

Does anyone know how to make this? Can you guide me where I can buy the cable and the plastic tube and the staple needle and gun to attach the ends of cable to battery?

SOLUTION

membership

This solution is only available to members.

To access this solution, you must be a member of Experts Exchange.

SOLUTION

membership

This solution is only available to members.

To access this solution, you must be a member of Experts Exchange.

SOLUTION

membership

This solution is only available to members.

To access this solution, you must be a member of Experts Exchange.

SOLUTION

membership

This solution is only available to members.

To access this solution, you must be a member of Experts Exchange.

ASKER CERTIFIED SOLUTION

membership

This solution is only available to members.

To access this solution, you must be a member of Experts Exchange.

SOLUTION

membership

This solution is only available to members.

To access this solution, you must be a member of Experts Exchange.

SOLUTION

membership

This solution is only available to members.

To access this solution, you must be a member of Experts Exchange.

ASKER

the two connected battery is expensive, I thought I could make my own easily, seems as it isn't